SHAFT COUPLING:

A rotating piece of rod coupled to a machine is called shaft. It has a circular cross-section and always transmits power from one point to another along its length. The shaft length are not available beyond a certain limit due to manufacturing and transporting difficulties. If very long shafts are required for any application, two or more shaft pieces may be connected or coupled together to obtain the requisite length. The connection used for joining pieces of shaft together is known as shaft coupling.

Shaft couplings are used to join or connect two shafts in such a way that when both the shafts rotate, they act as one unit and transmit power from one shaft to the other. Shafts to be connected or coupled may have collinear axes, intersecting axes or parallel axes at a small distance. Based on the requirements, the shaft couplings are classified as: (i) rigid couplings, (ii) flexible couplings.

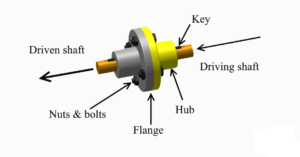

FLANGE COUPLING:

In a flanged coupling, flanges are either fitted or provided at the ends of shafts. The flanges are fastened together by means of a number of bolts and nuts. The number and size of the bolts depend upon the power to be transmitted and hence, the shaft diameter.

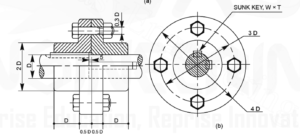

UNPROTECTED FLANGE COUPLING

It consists of two similar discs called flanges. Each flange is keyed to needs of shafts to be coupled. To secure both the flanges together, both the flanges have four to six holes to receive the bolts. When these flanges are bolted together, they form a rigid joint between the two shaft ends.

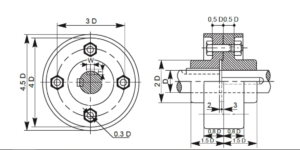

PROTECTED FLANGE COUPLING

In this coupling, the outer surface of each flange is protected outward axially to cover bolt heads and nut and to form a flat outer surfaces like that of pulley. It may be used as pulley also. The depression in the centre of one flange and projection on the other is formed for helping in obtaining perfect alignment between shafts.

RELATED VIDEOS: