METAL CUTTING

HACKSAW:

The bar stocks, rods, tubes, iron flats, metal sheets etc. are always required in desired lengths in a fitting shop. Hacksaw is the common tool which is used in the fitting shop to cut the job in required or desired length.

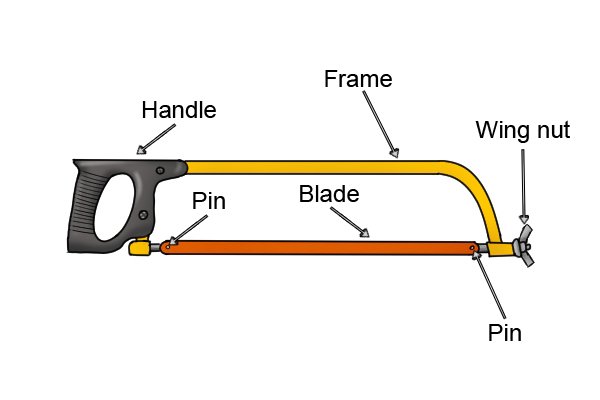

Parts of Hacksaw

It consists of a metal frame, fitted with a wooden handle. The blade fits over two pegs which project from the pins sliding in the ends of the frame. The wing nut at the front end to the frame is for tensioning the blade.

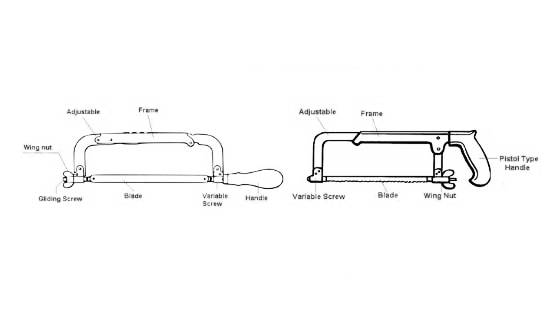

TYPES OF FRAMES:

The frame of the hacksaw can be either FIXED TYPE, which can accommodate the same length of the blades always, or can be ADJUSTABLE TYPE, which is capable of accommodating different lengths of blades.

TYPES OF BLADES:

Hacksaw Blade is the main part. They are manufactured in two different categories ALL HARD and FLEXIBLE,. All Hard blades are hardened all over while the Flexible Blades are hardened only along the teeth and the remaining portion is tempered to make it tough and comparatively softer.

PUSH TYPE BLADES:

PUSH TYPE BLADES are those which cut in forward stroke only. In these, the teeth always point away from the operator.

PULL TYPE BLADES:

PULL TYPE BLADES are those which cut in backward stroke only. In these, the teeth always point towards the operator.

The blades are specified by its length and the pitch. The length of the blade is the distance between the outside edges of the holes which fit over the pins. The most usual blade for hand work is 250 mm long and 12.5 mm wide. The pitch is measured by the number of teeth per 25 mm length.

The points of the teeth are bent to cut a wide groove and prevents the body of the blade form rubbing or jamming in the saw cut. This bending of the teeth to the sides is called setting of the teeth. Usually alternate teeth are set to right and left, every third or fifth tooth left straight to break up the chips and help the teeth to clear themselves. The fine toothed blades for cutting thin metal are sometimes made with a wavy set minimize stripping of the teeth from the blade.

The choice of the blade for any particular class of work depends upon the pitch of the teeth and at least two or three teeth should be in contact with the surface being sawn. If this is not attained, the teeth will be stripped from the blade and sawing too sharply over a corner will also result in teeth being torn off.

The blades in common use are generally 0.7 m thick, 12.7 mm wide and 20 to 30 cm long. About 5 to 7 teeth form per cm length of blade form the COARSE GROUP and 8 to 12 teeth per cm form the FINE GROUP of teeth.

APPLICATIONS:

|

6 teeth per cm |

For rolled and structural steel having thick sections, wrought iron |

|

7 teeth per cm |

For general cutting in most of the metals like steel, cast iron, aluminum, Babbitt metal and all other general cutting work |

|

10 teeth per cm |

For medium sections of metal sheets, pipes and metals likes brass and copper etc. |

| 12 teeth per cm |

For thin sections of metals sheets, tubes and conduits etc. |

RELATED VIDEOS:

For More Information- CLICK HERE