EXPERIMENT

OBJECTIVE:

To study the constructional features and working details of heat treatment furnaces.

APPARATUS REQUIRED:

The heat treatment furnaces commonly used in the metallurgical lab are as follows:

- Box type furnace

- Pit type furnace

CONSTRUCTIONAL FEATURES:

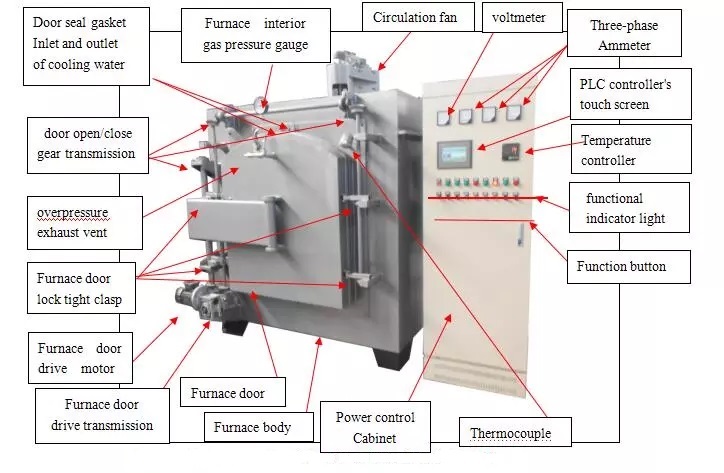

- BOX TYPE FURNACE:

SPECIFICATIONS:

|

Type of furnace |

Box type furnace (Electric Heating) |

| Rating |

16 KW |

|

Size |

Effective internal dimensions- Width = 300 mm, Depth = 600 mm. Height = 250 mm |

| Heating element |

Chromium, nickel wire |

|

Maximum service temperature |

1100° C |

| Heating time from cold, for the empty and closed furnace up to a temperature of 800° C |

2.5 hours approx. |

|

Supply voltage |

400 V, 3 phase, 50 Hz |

| Weight |

925 kg approx. |

The furnace is provided with a ventilation opening and an inspection hole in the door.

For temperature measurement the furnace is equipped with one thermocouple, provided with 5 m of compensating leads.

DETAILS OF CONSTRUCTION

- The shape of the furnace is fabricated like a box. Its outer body is made up of 1/4 ” thick mild steel plate. At the front is provided a door with a centre hole. The door is operated with the help of a door handle and is operated with two large springs for its reversible operation.

- On one side of the furnace body there is a cut out switch operated by the door handle to cut off the supply and vice versa to the heating element of the furnace. The cut out switch is so provided as to ensure the safety of worker/operator while opening/closing of the furnace door.

- In the interior of the furnace are fixed refractory bricks with the help of fire clay. Similarly at the back of door are fixed these refractory bricks and on these the heating element is mounted wound on the insulation material. The power supply to the heating element comes from the main control panel.

- A thermostat is provided inside the furnace chamber regulate inside temperature of the furnace.

- On main control panel there are two indicating lamps; one indicated whether the control panel is supplying electricity to the furnace and the other indicated whether the furnace is in off or on position.

- On the control panel is provided a main graduated scale having two pointers – one movable and the other idle. The movable pointer moves on the graduated scale as the furnace starts getting heated up and thus indicated the instantaneous temperature of the furnace. The idle pointer is for setting up the required range of temperature.

- A vent hole is provided at top to act as an outlet passage for the gases being formed inside the furnace.

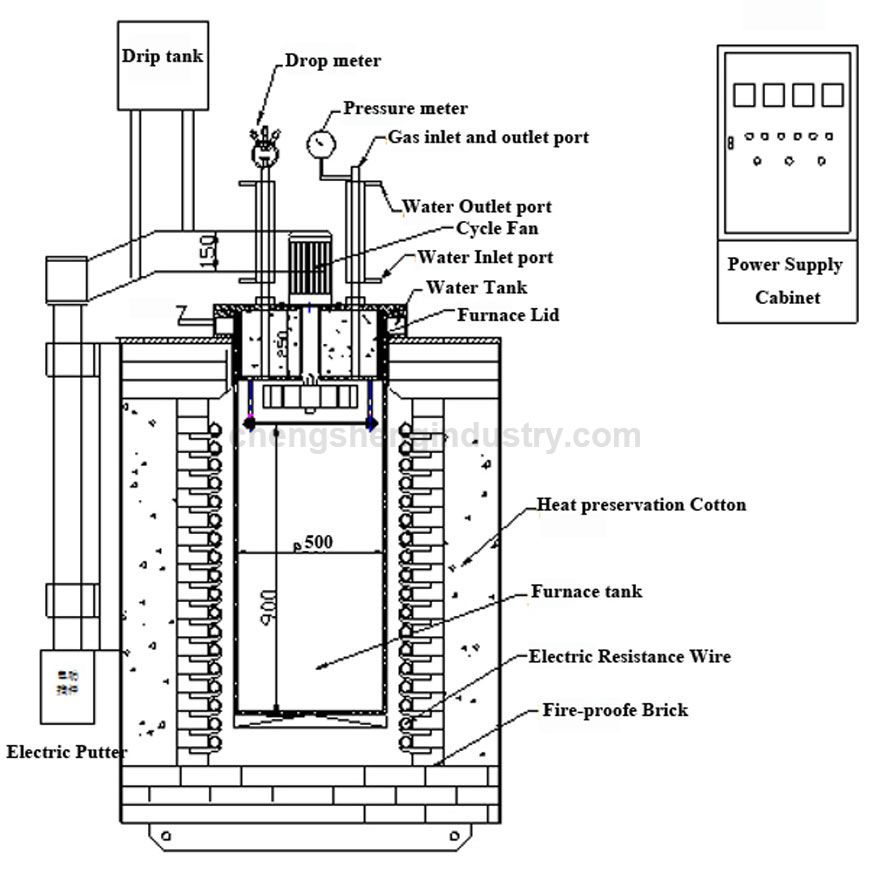

- PIT TYPE FURNACE:

SPECIFICATIONS:

|

Type of furnace |

Pit type furnace with forced air circulation |

| Rating |

9 KW |

|

Size |

Effective internal dimensions- Diameter = 300 mm, Depth = 400 mm.

|

| Capacity |

28 liters |

|

Heating element |

Encased coiled wire |

| Operating temperature |

100 – 700° C |

|

Heating time from cold, for the empty and closed furnace up to a temperature of 800° C |

30 minutes approx. |

| Supply voltage |

400 V, 3 phase, 50 Hz |

|

Weight |

500 kg approx. |

Practical Components

- Flanged motor with lengthened shaft including pin, ring and nut.

- Fan

- Bracket

- Air guiding cylinder

- Strip plate

- Gauge grate

- Muffle heating element

The bottom of the furnace consists of special bricks on which the muffle heating element has been accommodated.

Working Operation

- Make sure that all the electrical connections are tightened properly for putting on the supply from main control panel to the furnace.

- Fix the position of the idle pointer on the graduated scale of the pyrometer to fix the limit of temperature required in the furnace.

- Put on the main supply from the control panel to the heating element inside the furnace chamber.

- After opening the door of the furnace put the specimen inside the furnace chamber with the help of a tong.

- Close the door of the furnace and allow the temperature of the furnace to rise gradually so as to heat the specimen kept inside.

- For judging the color and proper heating of the specimen, check through the peep hole from time to time.

PRECAUTIONS:

- Make sure that al the electrical connections are properly made.

- Never operate the furnace bare footed.

- Use fir tongs and safety gloves while placing in or taking out the specimen from the furnace.