SIMPLE LIFTING MACHINES

LIFTING MACHINES

-

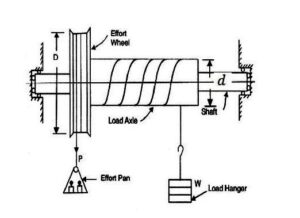

SIMPLE WHEEL AND AXLE:

In simple wheel and axle, the wheel and axle are keyed to the same shaft. The shaft is mounted on ball bearings, order to reduce the frictional resistance to a minimum. A string is wound round the axle , which carries the load to be lifted. A second string is wound round the wheel in the opposite direction to that of the string on the axle.

Let,

D = Diameter of effort wheel,

d = Diameter of the load axle,

W = Load lifted, and

P = Effort applied to lift the load.

One end of the string is fixed to the wheel, while the other is free and the effort is applied to this end. Since the two strings are wound in opposite directions, therefore a downward motion of the effort (P) will raise the load (W).

Since the wheel as well as the axle are keyed to the same shaft, therefore when the wheel rotates through one revolution, the axle will also rotate through one revolution.

We know that,

Distance moved by the effort in one revolution of effort wheel, = πD

Distance moved by the load in one revolution = πd

Velocity Ratio (V.R) = [frac up=”Distance moved by the effort” down=”Distance moved by the load”] = [frac up=” πD” down=” πd”] = [frac up=”D” down=”d”]

Mechanical Advantage (M.A) = [frac up=”Load” down=”Effort”] = [frac up=”W” down=”P”]

Efficiency, η = [frac up=”M.A.” down=”V.R.”]

-

DIFFERENTIAL WHEEL AND AXLE:

This machine is an improved form of simple wheel and axle, in which the velocity ratio is intensified with the help of load axle. In this case, the load axle is made up of two parts of different diameters. Like simple wheel and axle, the wheel, and the axles are keyed to the same shaft, which is mounted on ball bearings in order to reduce the frictional resistance to a minimum.

The effort string is wound round the wheel. Another string wound round the axle 1, which after passing round the pulley (to which the weight W is attached) is wound round the axle 2 in opposite direction to that of the axle 1; care being taken to wind the string on the wheel and axle 2 in the same direction. As a result of this, when the string unwinds from the wheel, the other string also unwinds from the axle 2. But it winds on the axle 1.

Let

D = Diameter of the effort wheel A,

d1 = Diameter of the axle 1,

d2 = Diameter of the axle 2,

W = Weight lifted by the machine, and

P = Effort applied to lift the weight.

We know that,

Distance moved by the effort in one revolution of effort wheel = πD

∴ Length of string, which will wound on axle 1 in one revolution = πd1

and

Length of string, which will unwound from axle 2 in one revolution = πd2

∴ Length of string which will wound in one revolution = π d1 – π d2 = π (d1 – d2)

and

Distance moved by the weight = [frac up=”1″ down=”2″] π (d1 – d2) = [frac up=”π” down=”2″] (d1 – d2)

∴ Velocity Ratio (V.R) = [frac up=”Distance moved by the effort” down=”Distance moved by the load”] = [frac up=”πD” down=”π (d1 – d2) /2″] = [frac up=”2D” down=”(d1 – d2)”]

Mechanical Advantage (M.A) = [frac up=”Load” down=”Effort”] = [frac up=”W” down=”P”]

Efficiency, η = [frac up=”M.A.” down=”V.R.”]

-

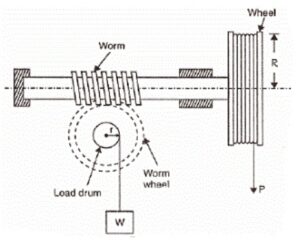

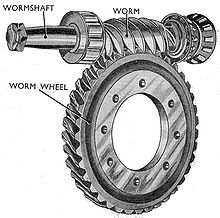

WORM AND WORM WHEEL

It consists of a square threaded screw (known as worm) and a toothed wheel (known as worm wheel) geared with each other. A wheel is attached to the worm, over which passes a rope as shown in the figure. Sometimes, a handle is also fixed to the worm (instead of the wheel). A load drum is securely mounted on the worm wheel.

Let,

D = Diameter of the effort wheel,

r = Radius of the load drum

W = Load lifted,

P = Effort applied to lift the load, and

T = No. of teeth on the worm wheel

We know that,

Distance moved by the effort in one revolution of the wheel (or handle) = πD

If the worm is single-threaded (i.e., for one revolution of the wheel A, the screw S pushes the worm wheel through one teeth), then the load drum will move through = [frac up=”1″ down=”T”] revolution

and

Distance through which the load will move = [frac up=”2πr” down=”T”]

∴ Velocity Ratio (V.R) = [frac up=”Distance moved by the effort” down=”Distance moved by the load”] = [frac up=”πD” down=”2πr /T”] = [frac up=”DT” down=”2r”]

Mechanical Advantage (M.A) = [frac up=”Load” down=”Effort”] = [frac up=”W” down=”P”]

Efficiency, η = [frac up=”M.A.” down=”V.R.”]

RELATED VIDEOS FOR LIFTING MACHINES:

For More Information:- CLICK HERE