OPERATIONS MANAGEMENT

BATHTUB CURVE

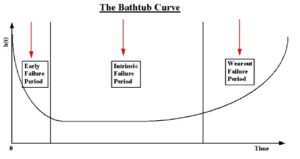

The bathtub curve describes a particular form of a failure rate function which comprise three parts: early failure, random failure and wear out failure.

It is the usual experience with equipment that the failure rate is quite high when the equipment is new or newly installed. The failure rate is greater during the initial starting period of infancy but after this initial period is over, the failures are relatively quite low. Such a behavior can be approximated to a hyper exponential distribution. Such behavior is a sign of the design defects or installation defects. Therefore, those that had these inherent defects failed when the equipment were run. Those that failed much later were those that did not have the design or installation defects. This is somewhat similar to the infant mortality in humans.

Bathtub Curve

At the other extreme, many equipment fail due to ageing and wear out. The failure or death may be at a mean or average age, though some should could fail by a symmetrical bell shaped normal distribution.

In between the infancy and old age also the equipment may fail, but it is neither due to inherent design or installation defects not due to being worn out. The cause is external to the equipment and therefore, can be approximated to a negative exponential distribution. This is again similar to the behavior in humans, where they may die due to external causes such as an epidemic or traffic accidents while they are neither old nor infants.

The three distributions mentioned above, hyper-exponential, negative exponential and normal, can be confirmed into one distribution, termed as the weibull distribution. Hence, the bath tub curve depicting the failure rate can be represented by a weibull distribution. Weibull distributions calculations are very lengthy and tedious. Fortunately weibull graphs are available for determining mean time between failure. This would provide good data for determining system reliabilities, availabilities, expected lives, etc. Failure statistics can also be used in the diagnosis of the nature of a recurrent equipment failure and also in the prescription of solutions to maintenance problems.

ACTIVITIES INVOLVED IN MAINTENANCE MANAGEMENT

- Planning maintenance work on a long term basis.

- Issuing maintenance work orders.

- Storing maintenance materials.

- Deciding inspection methods and routine.

- Developing and issuing standard instructions.

- Measuring efficiency of maintenance.

- Controlling maintenance personnel.

- Maintaining maintenance records.

RELATED VIDEOS FOR BATHTUB CURVE:

For More Information- CLICK HERE