KEYS:

- A key is a piece of mild steel inserted between the shaft and hub or boss of the pulley to connect these together in order to prevent relative motion between them.

- Keys are used as temporary fastenings and are subjected to considerable crushing and shearing stresses.

- Key is inserted in to the groove cut in the two mating parts which are to be fastened.

- The main function of the key is to transmit torque between a rotating shaft and a machine element assembled on it.

- Key is also a safety feature because when overloading occurs, the key breaks before the part of shaft breaks.

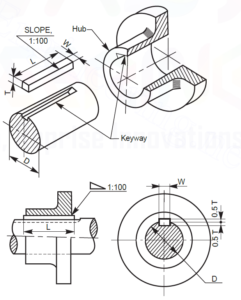

DEPTH OF IMMERSION

The depth of the key within the shaft is called depth of immersion of the key. A key is usually half in and half out of the shaft measure at the side and not when measured on the Centre line. The key is generally proportional to shaft on which it is to be fitted.

TYPES OF KEYS

Keys are generally classified into two main categories according to the shape and the duty for which they are used:

(a) SUNK KEY (b) SADDLE KEY

(a) SUNK KEY:

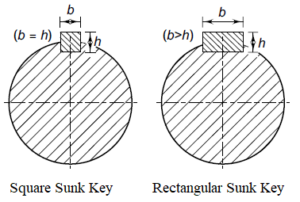

When the key is inserted in the groove cut in the shaft as well as in the hub, the key is called sunk key. The key may be square or rectangular in cross section. The square sunk keys are widely used. The sides of both types of keys are parallel. The taper on key or tapered key means the thickness of key reduces along its length. Both square an rectangular sunk keys are placed half in the shaft and half in the mating part or hub.

The sunk keys are of the following types:

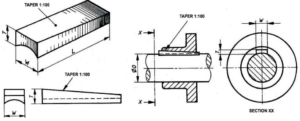

(i) PARALLEL SUNK KEY:

Parallel Sunk Key is uniform in width and thickness throughout. It is thus taper less and is used where the pulley or other mating piece is required to slide along the shaft. It may be rectangular or square cross-section and their ends may be squared or rounded.

Rectangular Parallel Sunk Key:

Proportions:

Let the diameter of the shaft = D

Width of key, W = D/4

Thickness of key, T = D/6

Length of key, L = D to 1.5 D

Square Parallel Sunk Key:

Proportions:

Let the diameter of the shaft = D

Width of key, W = D/4

Thickness of key, T = W

Length of key, L = D to 1.5 D

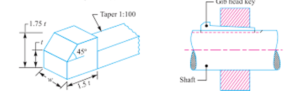

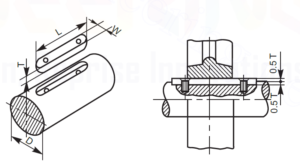

(ii) GIB HEAD KEY:

It is a rectangular sunk key with a head at one end known as Gib-head. It is usually provided to facilitate the removal of key.

Proportions:

Let the diameter of the shaft = D

Width of key, W = D/4

Thickness of key, T = D/6

Length of key, L = D to 1.5 D

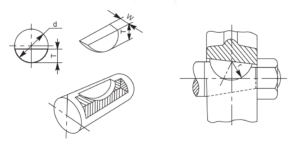

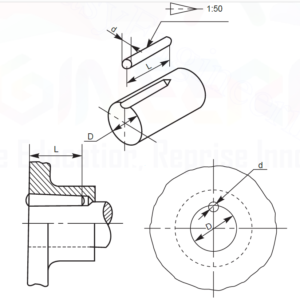

(iii) WOODRUFF KEY:

The woodruff key is an easily adjustable key. It is a piece from a cylindrical disc having segmental cross- section. It fits in the slot cut in the shaft so that the flat portion projects outside the shaft. This projected portion fits into the keyway cut in the hub of the wheel. It is in a way adjustable sunk key. It can tilt in the keyway so that its top face can lineup with the taper in the keyway cut in the hub of pulley, gear or other mating parts. These are for light applications.

Proportions:

Let the diameter of the shaft = D

Thickness of key, T = D/6

Radius of key, R = 2T = D/3

(iv) FEATHER KEY:

It is a key attached to one member of a pair and permitting relative motion axial movement thus it is particular kind of parallel key which permits axial moment . A feather key is secured either to the shaft or to the hub, the key being a sliding fit in the keyway of the moving piece.

Proportions:

Let the diameter of the shaft = D

Width of key, W = D/4

Thickness of key, T = D/6

Height of key, H = 1.5 T

Length of key, L = D to 1.5 D

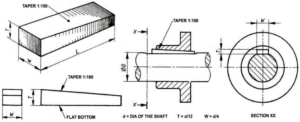

(b) SADDLE KEY:

A Saddle key is a key which fits in the keyway of the hub only. In this case, there is no keyway on the shaft. It is likely to slip round the shaft under load. Therefore it is used for comparatively light loads.

The saddle keys are of the following types:

(i) HOLLOW SADDLE KEY:

This key has its underside hollow out so that it can be placed on the curved surface of the shaft. The keyway is cut in the mating piece (hub) only. Hollow saddle key is used for light duty. It is simply mounted on the shaft and fitted in the recess provided in the hub of the wheel. The main feature of this type of key is that we can alter the position of the wheel easily. The relative rotation is prevented by the friction between the key and the shaft.

Proportions:

Let the diameter of the shaft = D

Width of key, W = D/4

Thickness of key, T = D/12

Length of key, L = D to 1.5 D

(ii) FLAT SADDLE KEY:

In this key, the lower surface is flat and fits on the flat surface provided on the shaft. It is used for light work. It is a taper key.

Proportions:

Let the diameter of the shaft = D

Width of key, W = D/4

Thickness of key, T = D/12

Length of key, L = D to 1.5 D

ROUND KEYS:

It is a key of circular cross-section. These can be parallel or taper and fitted on round holes drilled partly in the shaft and partly in the hub of the wheel. Round keys are generally used for light duty, where the loads are not considerable.

Proportions:

Let the diameter of the shaft = D

Width of key, W = D/6

Length of key, L = D to 1.5 D

RELATED VIDEOS: