FASTENING

he process of joining two parts of a machine or structure by means of various devices known as fastening. The devices which are used for the fastening process are known as fasteners.

Fastening is of the following types:

(a) Permanent Fastening (b) Temporary Fastening

PERMANENT FASTENING:

The process of joining two or more than two parts of machine or structure by means of various fasteners permanently is known as permanent fastenings. In permanent fastening, the parts once joined together cannot be separated from each other. If required to be separated, the fastening is bound to be broken.

EXAMPLES: Riveting, Soldering, Brazing, Welding etc..

TEMPORARY FASTENING:

The process of joining two or more than two parts of machine or structure by means of various fasteners temporarily is known as temporary fastenings. In this process, the parts joined together can be separated easily when required without breaking any part of fastener.

EXAMPLES: Bolts and Nuts, Studs and Nuts, Keys, Pins etc.

RIVETED JOINTS

DEFINITIONS

The definitions of the terms, associated with riveted joints are given below:

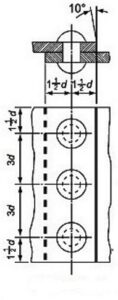

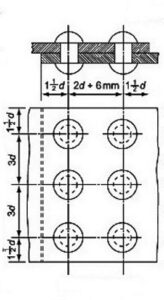

- PITCH

It is the distance between the centres of the adjacent rivets in the same row. It is denoted by ‘P’ and usually taken as 3D, where D is the rivet diameter.

- MARGIN

It is the distance from the edge of the plate to the centre of the nearest rivet. It is usually taken as 1.5D, where d is the rivet diameter. It is denoted by m.

- CHAIN RIVETING

If the rivets are used along a number of rows such that the rivets in the adjacent rows are placed directly opposite to each other, it is known as chain riveting.

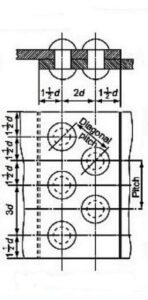

- ZIG ZAG RIVETING

In a multi-row riveting, if the rivets in the adjacent rows are staggered and are placed in between those of the previous row, it is known as zig-zag riveting.

- ROW PITCH

It is the distance between two adjacent rows of rivets. It is denoted by ‘Pr’ and is given by, Pr = 0.8p, for chain riveting Pr = 0.6p, for zig-zag riveting.

- DIAGONAL PITCH

This term is usually associated with zig-zag riveting and is denoted by ‘Pd’. It is the distance between the centre of a rivet in a row to the next rivet in the adjacent row.

- BACK PITCH

It is the distance between rows and rivets measured perpendicular to the plate seam. It is denoted by Pb.

TYPES OF RIVETED JOINTS

Rivet joints are of two types

(a) Lap Joints

(b) Butt Joints

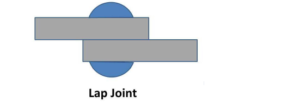

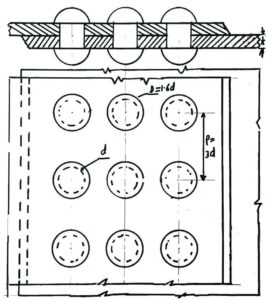

LAP JOINTS

The edge of one plate is placed over the edge of the second plate i.e. they overlap each other and all rivets pass through both the plates and the joint thus formed is known as Lap Joint. The distance by which both the plates overlap each other, this distance of overlap is called overlap. If overlap requirement is more, there may be two rows of rivets and if distance of overlap is les, there may be only one row of rivets.

Lap joints are of following types:

- Single Riveted Lap Joint – One row of rivets

- Double Riveted Lap Joint – Two rows of rivets placed in chain type

- Double Riveted Lap Joint – Two rows of rivets placed in zig zag formation

- Triple Riveted Lap Joint – Three rows of rivets and rivets placed in chain type

- Triple Riveted Lap Joint – Three row of rivets and rivets placed in zig zag formation

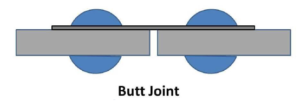

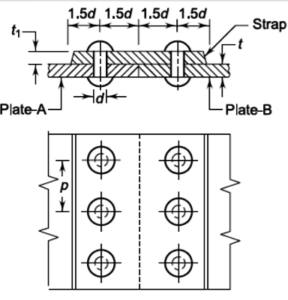

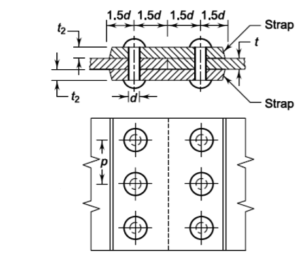

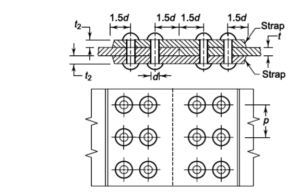

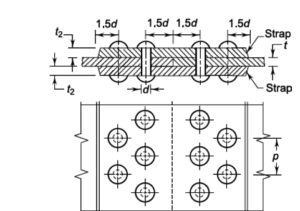

BUTT JOINTS

The edge of the connecting plates butt against each other and covered with cover plates on one or both sides. In the butt joints, at least two rows of rivets, on each of the connecting plates being joined are necessary to make a butt joint.

Butt joints are of following types:

- Single Riveted Single Cover Butt Joint: 2 Rows of Rivets

- Single Riveted Double Cover Butt Joint: 2 Rows of Rivets

- Double Riveted Double Cover Butt Joint Chain Type: 4 Rows of Rivets

- Double Riveted Double Cover Butt Zig-Zag Type: 4 Rows of Rivets

RELATED VIDEOS FOR RIVETED JOINTS: