FASTENING

The process of joining two parts of a machine or structure by means of various devices known as fastening. The devices which are used for the fastening process are known as fasteners.

Fastening is of the following types:

(a) Permanent Fastening (b) Temporary Fastening

PERMANENT FASTENING:

The process of joining two or more than two parts of machine or structure by means of various fasteners permanently is known as permanent fastenings. In permanent fastening, the parts once joined together cannot be separated from each other. If required to be separated, the fastening is bound to be broken.

EXAMPLES: Riveting, Soldering, Brazing, Welding etc..

TEMPORARY FASTENING:

The process of joining two or more than two parts of machine or structure by means of various fasteners temporarily is known as temporary fastenings. In this process, the parts joined together can be separated easily when required without breaking any part of fastener.

EXAMPLES: Bolts and Nuts, Studs and Nuts, Keys, Pins etc.

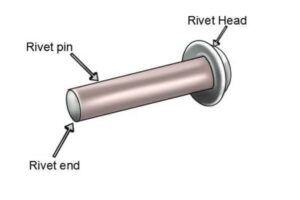

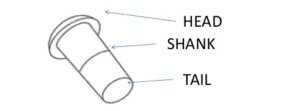

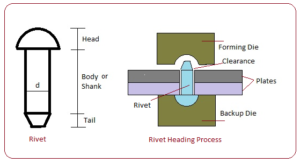

RIVETS

The round bar or steel or wrought iron with a head on one side and tail on the other end is known as rivet. Therefore, the rivet consists of

(a) Head

(b) Shank or Body

(c) Tail

It is inserted in a hole drilled through the parts which are to be connected. The insertion is done by hammering or by pressing with a machine.

APPLICATION OF RIVETS:

The rivets are widely used in structural works like roof trusses, bridges, ship and aircraft building, boilers, pressure vessels, air receivers and many other engineering works.

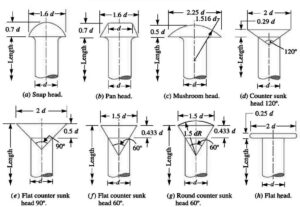

TYPES OF RIVETS

RIVETING

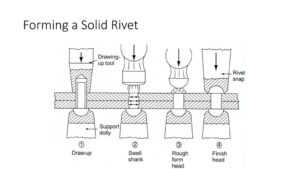

Riveting is the process of forming a riveted joint. For this, a rivet is first placed in the hole drilled through the two parts to be joined. Then the shank end is made into a rivet head by applying pressure, when it is either in cold or hot condition.

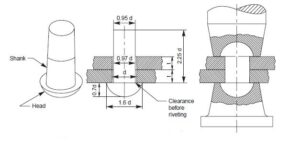

Pressure may be applied to form the second rivet head, either by direct hammering or through hydraulic or pneumatic means. While forming the rivet head, the shank will bulge uniformly. Hence, a certain amount of clearance between the hole and shank must be provided before riveting.

Hot riveting produces better results when compared to cold riveting. This is because, after hot riveting, the contraction in the shank length tends to pull the parts together, making a tight joint.

For riveting the two plates together, the diameter of rivet hole is kept slightly more than the rivet head. The rivet is made red hot and inserted into the hole in the plates form bottom side. The other end of the rivet is then formed by means of rivet hammering tool known as dolly by means of electric hammering.

CAULKING AND FULLERING

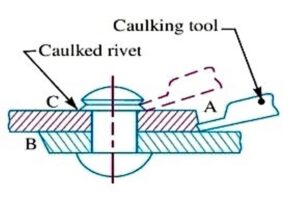

Riveted joints must be made air tight in applications such as boilers and other pressure vessels. But it is not always possible to achieve a perfectly leak proof joint even if riveting is very carefully done. In order to prevent the leakage of steam and other high pressure liquids through riveted joints, the plates are generally forces together by means of various caulking and fullering operations.

CAULKING:

The outer edges of the plates used in boiler and other pressure vessels are beveled. To produce air tight riveted joints, these beveled edges of the plates are caulked. Caulking is an operation in which the outer beveled edges of the plates are hammered and driven-in by caulking tool.

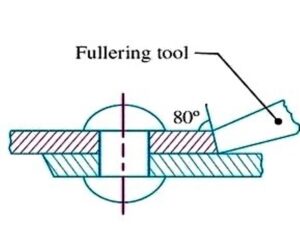

FULLERING:

Similar to caulking, fullering is also used to produce air tight joints. Unlike the caulking tool, the width of the fullering tool is equal to the width of the beveled edges of the plates.

RELATED VIDEOS FOR RIVETS AND RIVETING: