FITTING SHOP

FILING

It is required after chipping or cutting operation to remove burr and clean the face of the cuts and finish the final shape of the workpiece. The filing operation consists of the following steps:

- The work should be held firmly in the vice with the minimum amount of projection and with the surface to be filed truly horizontal.

- The file handle should be grasped in the right hand and the end of the file handle should be pressed against the palm of the hand. The pressure on the work should be applied by holding the end of the blade with the left hand. The worker should take his position on the left side of the vice with the feet firmly planted, slightly apart.

- A stroke should be made by a slight movement of the right arm from the shoulder and by a sway of the body towards the work, each of these movements being about equal.

- The file must remain horizontal throughout the stroke with pressure only applied on the forward motion.

- The file on the return stroke remains in contact with the work but the pressure is relieved from it.

- In order to test the surface of work during filing, a straight edge should be placed on it occasionally and the line of contact is viewed for daylight. When any considerable amount of metal has to be removed, the bulk of it should be removed by a rough or bastard cut file and the surface progressively brought to a finish by second cut and smooth files.

Methods of Filing

There are several methods of filing, each with a specific purpose:

1. HOLDING THE FILE: For heavy work and to remove more metal, a high pressure is used. For light and fine work, a light pressure is applied.

2. FILING INTERNAL CURVES: A part of half round file only makes contact as shown during filing operation. Movement of the file is indicated by arrows.

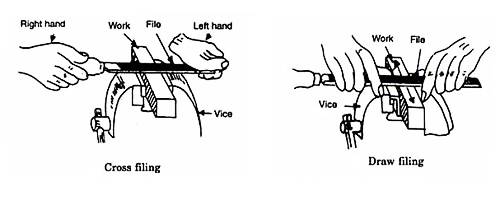

3. CROSS FILING: It is the most common method of filing. Cross filing is carried out across two diagonals, to produce medium surface finish. It is used when large amounts of metal are to be removed. By cross filing ‘rounding’ the surface is reduced.

4. STRAIGHT FILING: When a short length of work piece is required to have a flat surface, straight filing is used. File marks made during cross filing may be removed, to produce a relatively smooth surface.

5. DRAW FILING: It is done to get a finely finished surface. It produces a smoother surface finish than straight filing. A smooth or dead smooth flat file is used for this.

THE GRIP:

For files needing two-handed operation, the handle should be grasped in one hand and the point of the file in the other hand. The file handle should be rested in the palm with the thumb pointing along the top of the handle and the fingers gripping the underside. The point of the file should be grasped between the thumb and the first two fingers with the thumb being on the top of the file.

When heavy filing strokes are required, the thumb on the point is normally in line with the file; the tip of the thumb pointed forward. For lighter strokes however, the thumb can be turned to as much as right angles to the direction of the stroke If the file is being used one-handed for filing pins, dies or edged tools not being held in a vise, the forefinger, and not the thumb is placed on top of the handle in line with the file.

CARRYING THE FILE:

For normal flat filing, the operator should aim to carry the file forward on an almost straight line in the same plane, changing its course enough to prevent grooving. Too much pressure often results in a rocking motion causing a rounded surface.

KEEP THE FILE CUTTING:

One of the quickest ways to ruin a good file is to apply too much pressure, or too little, on the forward stroke. Different materials of course require different touches; however, in general, just enough pressure should be applied to keep the file cutting. If allowed to slide over the harder metals the teeth of the file rapidly become dull, and if they are overloaded by too much pressure, they are likely to chip or clog. On the reverse stroke, it is best to lift the file clear of the workpiece , except on very soft metals. Even then pressure should be very light, never more than the weight of the file itself.

DRAW FILING:

Draw filing consists of grasping the file firmly at each end and alternatively pushing and pulling the file sideways across the work. Since files are made primarily to cut on a longitudinal forward stroke, a file with a short-angle cut should never be used, as it will score and scratch instead of shaving and Shearing.

When accomplished properly, draw filing produces a finer finish than straight filing. Normally, a standard Mill Bastard file is used for draw filing, but where a considerable amount of stock has to be removed; a Flat or Hand file (Double Cut) will work faster. However, this roughing down leaves small ridges that will have to be smoothed by finishing with a Single Cut Mill file.

CARE OF FILES:

The following points should be kept in mind while using the files:

- The files should not be used without handle or with loose fitting handle.

- A file should never be used on hardened steel, hard surface scale or allowed to strike against the hardened vice jaws.

- The new file should be used first on copper, brass and then on wrought iron and mild steel.

- Sometimes when soft metals are filed, they tend to clog the file teeth with minute particles of metal. These pins will not only spoil the efficient cutting action but they also spoil the work with scratches. These pins are removed and the file is cleaned with a thin hard wire brush or a file card.

- The file should not be allowed to rust and to prevent it, the file is coated with machine oil. The oil should be removed before the file is put to use by carbon tetrachloride or caustic soda.

- The worn out files may be reused by dipping it in hydrochloric acid. The worn out files are best suited for making scrapers, punches, chisels etc.

RELATED VIDEOS FOR FILING:

For More Information- CLICK HERE