FITTING SHOP

DEFINITION OF FITTING SHOP:

It is the process of assembling and fitting at a right place, different parts of a machine manufactured by different manufacturing process.

FILE:

Different types of files are the principal hand tools used by a fitter. Files are often used to put the finishing touches on a machined work piece, either to remove burrs or sharp edges or as a final fitting operation. Intricate parts or shapes are often produced entirely by skilled workers using files. In this unit you are introduced to the types and uses of files in metalworking.

The hand file is parallel in width and tapering slightly in thickness, towards the tip. It is provided with double cut teeth on the faces, single cut on one edge and no teeth on the other edge, which is known as the safe edge.

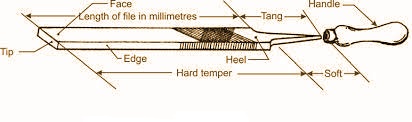

When a file is measured, the length is taken from the heel to the point, with the tang excluded. Most files are made from high-carbon steel and are heat-treated to the correct hardness range. They are manufactured in four different cuts: single, double, curved tooth, and rasp. The single cut, double cut, and curved tooth are commonly encountered in machine shops. Rasps are generally used with wood. Curved tooth files will give excellent results with soft materials such as aluminum, brass, plastic, or lead.

Detailed description of FILE

Files also vary in their coarseness: rough, coarse, bastard, second cut, smooth, and dead smooth. The files most often used are the bastard, second cut and smooth grades. Different sizes of files within the same coarseness designation will have varying sizes of teeth, the longer the file, the coarser the teeth.

For maximum metal removal a double-cut file is used. If the emphasis is on a smooth finish, a single-cut file is recommended. The face of most files is slightly convex because they are made thicker in the middle than on the ends. Because of this curvature only some of the teeth are cutting at any one time, which makes them penetrate better. If the face were flat, it would be difficult to obtain an even surface because of the tendency to rock a file while filing. Some of this curvature is also offset by the pressure applied to make the file cut. New files do not cut as well as slightly used ones, since on new files some teeth are longer than most of the others and leave scratches on a workpiece.

TYPES OF FILES

Files are classified according to their shape, cutting teeth and pitch or grade of the teeth, Figure shows the various types of files in use based on their shape.

-

SIZE:

The size of the file is indicated by its length. It is the distance from the point to the heel without tang. The length of the file, in general use, is 200 mm to 450 mm and 100 mm to 200 m for finer work.

-

CUT OF TEETH:

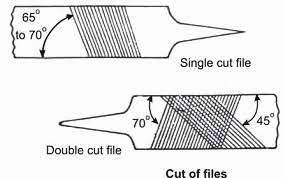

The files according to the cut of teeth are divided into two groups i.e. single cut and double cut.

In single cut files, the teeth are cut parallel to each other running across the faces and at angle of 65° to 70° to the centre line of the file. These files are frequently termed as flats and are particularly used for very hard metals.

In double cut files, there are two sets of teeth. The first set of teeth are similar to those of single cut files while the second set of teeth are cut diagonally across the first set of teeth at an angle of about 70° to the centre line of the file. All the teeth have negative rake i.e. sloping backwards by which they cut only on the forward stroke. It removes the metal faster and is used for general work.

-

GRADE OF CUT:

The single cut and double cut files, depending upon the pitch of the teeth may be classified as ROUGH, BASTARD, SECOND CUT, DEAD SMOOTH and SUPERFINE.

EFFECTIVE LENGTH OF FILE = 100 mm

S. No. GRADE OF FILE NUMBER OF CUTS PER 10 MM OF LENGTH USES

1

ROUGH 10 It is used for heavy reduction and filing casting after chipping. 2

BASTARD 18

It is used for reducing bulky work.

3

SECOND CUT 21

It is used for general work.

4

SMOOTH 30

It is used for smoothening surfaces and filing delicate works.

5

DEAD SMOOTH 35

These are used by toolmakers and silver smiths for high accuracy and finish.

6 SUPER SMOOTH 63

TYPE OF FILE DESCRIPTION AND USE:

1. HAND FILE:

Rectangular in section and tapered in thickness but parallel in width. The faces carry double cut teeth and one of the edges single cut. The other edge, known as safe edge, does not have any teeth and hence this file is also known as safe edge file. It is useful in filing a surface which is at right angles to an already finished surface.

2. FLAT FILE:

It is rectangular in section and tapered for 1/3 length in width and thickness towards the tip. The faces carry double cut teeth and the edges carry single cut teeth. It is a general purpose file.

3. SQUARE FILE:

It is square in section and carry double cut teeth on all the four faces. It is tapered for 1/3 of its length towards the point. Square files are used for filing corners and slots. It is also used to cut keyways in the work-piece.

4. THREE SQUARE FILE:

It is of equilateral triangular in section and tapers towards the tip. The faces are double cut and the edges sharp. These files are used to file angular hole, and recesses. Used for sharpening wood saws.

5. ROUND FILE:

It is tapered for 1/3 length with double cut on large coarse grades. Used for filing out round, elliptical and curved openings.

6. HALF ROUND FILE:

The half round file has one flat and one curved side. The flat side is double cut and the curved side is single cut. It is not a semicircle but is about 1/3 of circle. Second cut and smooth grades are used. This is an extremely useful double purpose file for flat surfaces and for curved surfaces which are too large for the round file to be used.

7. SWISS OR NEEDLE FILES:

150 mm long with double cut teeth. Used for filing corners, grooves, narrow slots, etc.

RELATED VIDEOS FOR FITTING:

https://drive.google.com/open?id=1uT-891IUMYtyNvxctLgTh2PsCFIwhMCr&authuser=0