EXPERIMENT

OBJECTIVE:

To determine the hardness of the given specimen using Rockwell hardness test.

APPARATUS REQUIRED:

- Rockwell hardness testing machine.

- Soft and hard mild steel specimen, brass, aluminum etc.

- Black diamond cone indenter.

THEORY:

The hardness of a material is its resistance to penetration under a localized pressure or resistance to abrasion. Hardness tests provide an accurate, rapid and economical way of determining the resistance of materials to deformation. There are three general types of test is conducted:

(i) Scratch hardness measurement.

(ii) Rebound hardness measurement

(iii) Indentation hardness measurement

In scratch hardness method the materials are rated on their ability to scratch one another and it is usually used by mineralogists only.

In rebound hardness measurement, a standard body is usually dropped on to the material surface and the hardness is measured in terms of height of its rebound.

The general means of judging the hardness is measuring the resistance of a material to indentation. The indenter is usually a ball, cone or pyramid of a material much harder than that being used. Hardened steel sintered tungsten carbide or diamond indenters are generally used. In indentation tests a load is applied by pressing the indenter at right angles to the surface being tested. The hardness of the material depends on the resistance which it exerts during a small amount of yielding or plastic straining. The resistance depends on friction, elasticity, viscosity and the intensity and distribution of plastic strain produced by a given tool during indentation.

ROCKWELL HARDNESS TEST:

Rockwell test is developed by the Wilson instrument co U.S.A in 1920. The test consists in forcing an indenter of standard cone or ball into the surface of a test piece in two operations and measuring the permanent increase of depth of indentation of this indenter under specified condition. From it Rockwell hardness is deduced. The ball (B) is used for soft material (e.g. mild steel, cast iron, aluminum, brass etc.) and the cone (C) for hard ones (High carbon steel, High speed steel etc.)

TEST BLOCKS:

- Standardized metal block shall be of a thickness note less than 6 mm. Block, if made of steel be demagnetized.

- The upper and lower surfaces of the blocks shall be flat with 0.,005 mm and parallel in thickness such that it should not vary more than 0.010 mm per 50 mm.

- The surfaces should be ground and polished.

TEST REQUIREMENTS:

- The test should be carried out at an ambient temperature at 20 ± 2° C in temperate climates and 27 ± 2° C in tropical climates.

- The testing machine shall be protected on a rigid support. The contact surfaces shall be clean and free from foreign matter (such as scale, oil and dust).

- The thickness of the test piece shall be at least 8 times the permanent indentation of depth. No deformation shall be visible at the back of the test piece after the test.

- The distance between the centers of the two adjacent indentations shall be at least 4 times the diameter of the indentation and the distance from the centre of the any indentation to the edge of test piece shall be at least 2.5 times the diameter of the indentation unless agrees otherwise.

PROCEDURE:

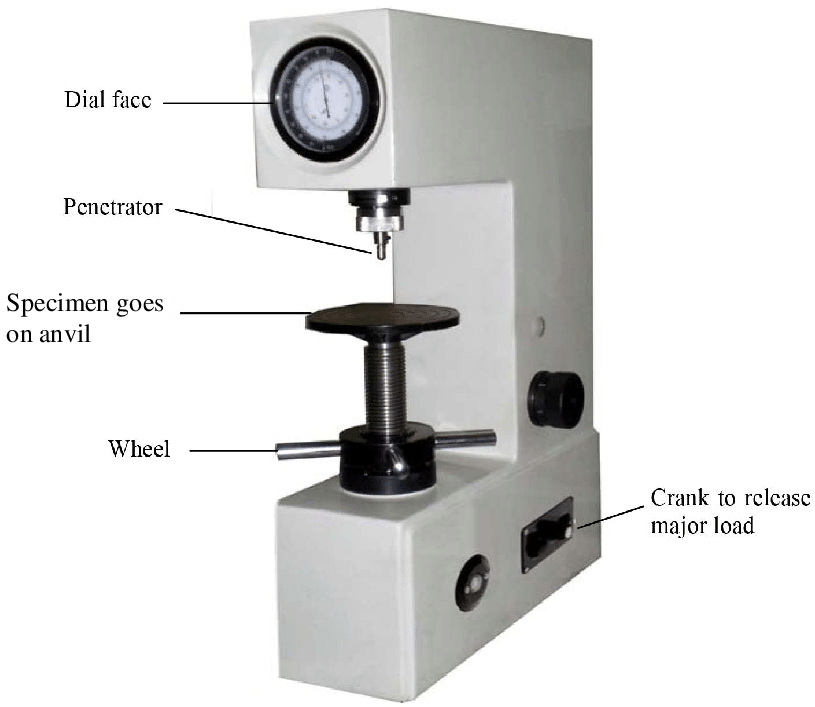

- Examine hardness testing machine.

- Place the specimen upon the anvil.

- Elevate the specimen so that it comes in contact with the penetrator and put the specimen under a preliminary or minor of 100 N ± 2 N without shock.

- Apply the major load 900 N by loading lever.

- Watch the pointer until it comes to rest.

- Remove the major load.

- Read the Rockwell hardness number on hardness scale.

OBSERVATION TABLE:

|

S. No. |

SPECIMENS | READING (HRB/HRC) |

MEAN |

||

|

1 |

2 |

3 |

|||

|

1 2 3 4 |

MILD STEEL

HIGH CARBON STEEL BRASS ALUMINUM |

HRB = HRC = HRB = HRB = |

|||

PRECAUTIONS:

- Successive impression should not be superimposed on another nor be made too close together when making hardness determinations.

- Nor should a measurements be made too close to the edge, or on a specimen on thin that impression come through the other side.

- Small irregularities, dirt, and scale should be avoided because of the greater sensibility of the Rockwell test.

- Note down the readings carefully.

RELATED VIDEOS FOR ROCKWELL HARDNESS TEST: